JLC Group dates back more than four decades to its foundation. A young and ambitious engineer, with a vision to contribute to the industrial and economic map of India started his venture in 1972 to manufacture Lead-in-wires for electric lamps.

This was the beginning of a long journey and since then JLC has continuously added various alloys to its product portfolio and has developed a strong relationship with its customers ranging from small companies to multi-national OEMs.

Foresight, diligence, and innovation have helped JLC become the leading manufacturer of Nickel-based alloys in wire, strips and ribbon forms.

-

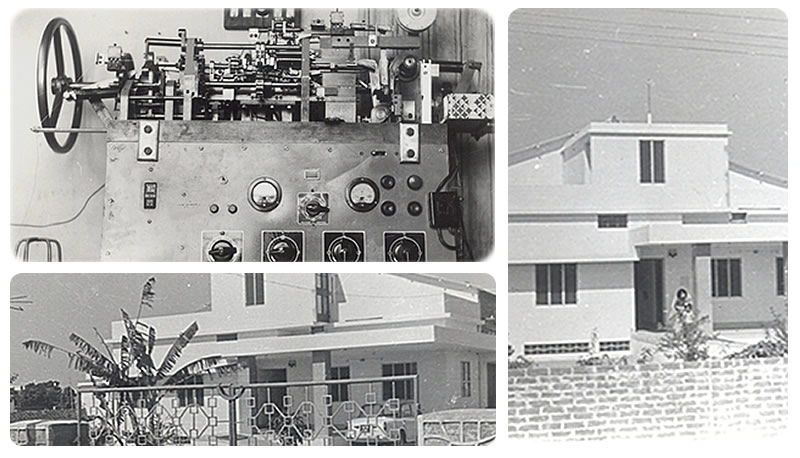

Lead-In-Wires for Electric Lamps

Production of Lead-In-Wires for Electric Lamps started with one machine

-

Nickel Plated Wires

Started production of Nickel-Plated wires

-

Nickel Alloy Melt Shop

Melting plant established for production of Nickel Alloys

-

Addition of NiMn, NiCu30Fe, NiFe

Nickel Alloys like NiMn, NiCu30Fe, NiFe added to the expanding product portfolio

-

Dumet Wire Plant

-

Lead-In-Wire Capacity Expansion

Expansion of Lead-in-Wire capacity to 150+ machines and further addition of lighting alloys

-

Nickel Chrome Alloys

Nickel-Chromium alloys added to the product portfolio

-

Spark Plug Alloys

Developed spark plug alloy wire based on powder metallurgy for a large renowned US spark plug manufacturer

-

ISO 9001:2000 Certified

Received ISO 9001:2000 Certification for product development and manufacture of Nickel-based Alloys

-

Thermocouple Alloys

Thermocouple Compensating and Extension Grade Alloys production launched

-

Melt Capacity Expansion

-

Strip Manufacturing Expansion

Expansion of strip manufacturing capacity with latest technology

-

Lead-in Wire Capacity Expansion

Expansion of Lead-in Wire manufacturing capacity to 300+ latest technology machines

-

Wire Drawing Capacity Expansion

Expansion of wire drawing capacity with induction of latest technology machines

-

Osram Sylvania (USA) Plant Acquisition

Expansion by acquisition of Osram Sylvania, USA machines

-

Lighting Product Capacity Increased

Manufacturing capacity of Dumet and other lighting raw materials increased

-

Nickel Plated Dumet Developed

In-house new product development of Nickel Plated Dumet. Supplier Award from "Royal Philips Automotive" for this project

-

Exports Drive 75% of Annual Turnover

-

IEEMA Certifies JLC Quality

JLC receives recognition and ISQA Quality certification from Indian Electrical and Electronics Manufacturers' Association (IEEMA)

-

JLC R&D Centre Accredited by Government

JLC's in-house Research & Development centre receives accreditation from Government of India

-

Melting Capacity Expansion

Expansion of Melting Capacity through advanced technology and in-house developments

-

JLC Becomes TOP Exporter

JLC receives the TOP Exporter GOLD Trophy from Engineering Export Promotion Council (EEPC) India

-

New Hot-Rolling Mill

Commissioning of new wire rod Hot-Rolling Mill with advanced technology and automation

-

Commissioning of new Strip Hot-Rolling Mill

-

Manufacturing Expansion

Expansion of manufacturing area by over 30,000 sq. feet

-

Upgradation of wire drawing technology and machinery

-

Upgraded R&D Lab

-

New Packaging & Material Handling Building

-

Wire Drawing Capacity Expansion

-

2 MW Solar Power Plant

Total 2 MW installted capacity covering 150,000 Sq.Ft. of area